Rapid Prototyping: How To Build A Quick Prototype For Your New Product

Prototyping. Many product designers live for it, some are afraid of it, and others don’t completely understand what it means and what it is intended to achieve.

No matter your attitude towards this process, there is an ongoing movement for a revolutionary method to prototyping – rapid prototyping.

The Purpose of Prototypes

First of all, once you are preparing to create a prototype, it is crucial not to lose track of the purpose of prototyping. The most compelling aspect of the prototyping method is that it drives the whole team from the thinking stage to the doing stage.

To build a prototype you must have a proper design that can be used for manufacturing a physical product. Once this objective is in mind, it can encourage breaking up the cycle of pondering, meeting, and feature-dreaming that might keep projects from progressing.

However, the prototype needs to be used for getting real feedback from an actual product instead of just remaining in the design stage. That is why rapid prototyping is so powerful for each product design team.

Continue reading to find more about the revolutionary process of rapid prototyping.

What Is Rapid Prototyping?

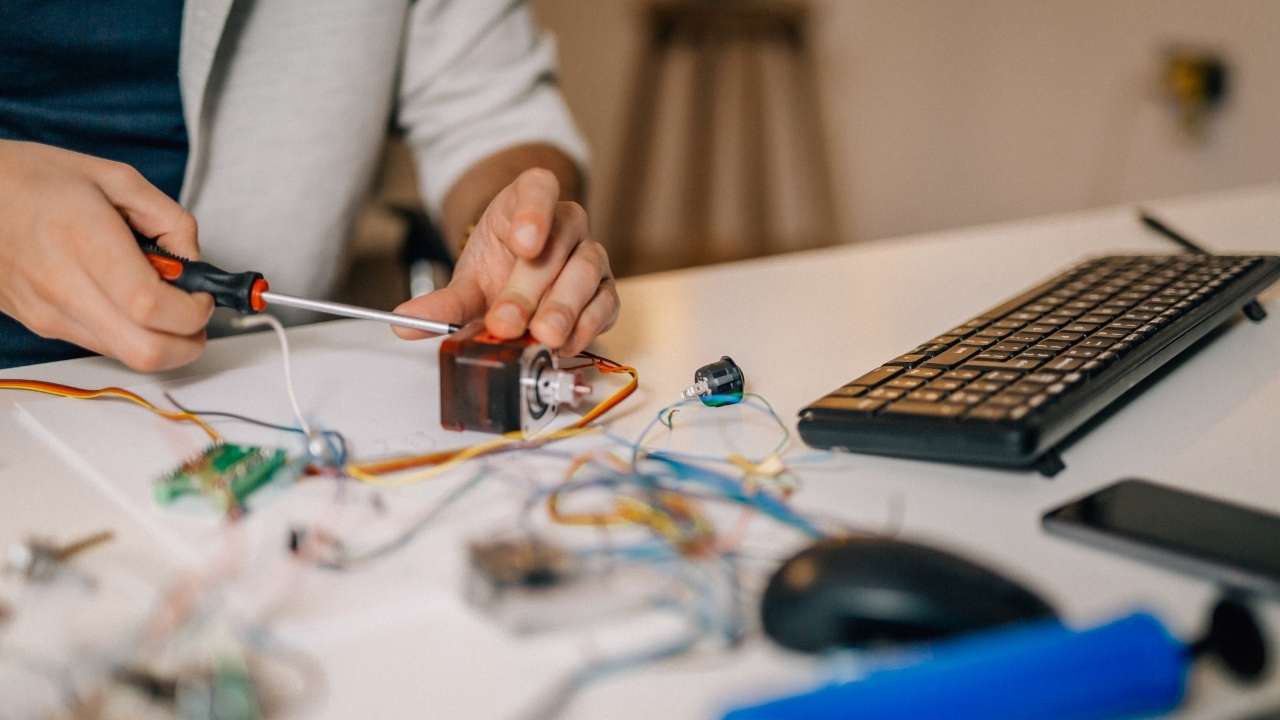

In the most fundamental sense, rapid prototyping is what it sounds like – the method of building a prototype in a short period of time. In reality, this typically means rapidly making a physical part using CAD and producing it with additive manufacturing (commonly called 3D printing.)

Rapid prototyping is utilized by a variety of different designers, engineers, inventors, and organizations to fastly manufacture a prototype that they can right away use to test, gather feedback, and iterate on their earliest design.

Rapid prototyping is now more available than ever, thanks to the extensive accessibility of 3D printing technology and its affordable prices globally. However, rapid prototyping China-based services are the number one go-to for many product designers across the globe because of their low prices and high-quality prototyping solutions. So, when product designers need prototyping services, they first consider China as the best country for rapid prototyping.

Rapid Prototyping Benefits

On the subject of the positive impacts of rapid prototyping, we have to start with the most obvious one: speed. Since the rapid prototyping method enables designers to have a physical product or part designed, manufactured, and tested in such a short timeframe they can promptly assess its benefits and faults. Plus, they can start planning the following iteration or production stage if the product is prepared for it.

The saying that it’s best to fail early and frequently definitely applies in product design. When it comes to rapid prototyping, the best thing is that you can discover if your prototype is a total failure in just a few days.

Think of how much time you could have wasted over an extended, more prolonged prototyping procedure only to discover the same result. In such a case, you would have to go back to your drafting board, being several days or weeks behind than you could have been with a faster prototyping procedure.

The other main advantage of rapid prototyping is low cost. The procedure of producing a prototype, testing it, and collecting feedback can be done at reduced expense when dealing with low quantity. So, if you can reduce financial risk by working that way, you will be able to maintain your projects under budget and spend the extra money for the more expensive elements of your product planning process.

Does Rapid Prototyping Have Any Downsides?

Although rapid prototyping can be very efficient, it has some potential downsides. The first downside is the chance of missing obvious design faults that could have been detected pre-prototype in a more in-depth process.

With rapid prototyping, the design method is streamlined, occasionally at the expense of early-stage examination. That results in the cost of the prototype that shows issues that else might have been caught earlier.

Rapid prototyping may also be limited to some industries or types of products. When it comes to products with a wide range of movable parts, interacting systems, or complex designs, rapid prototyping can’t handle all the manufacturing capabilities and technical difficulties required.

Final Words

So, the question is ‘Is the process of rapid prototyping right for you? Everything depends on your industry sector, business, and the product you want to manufacture.

For most moderately straightforward products which can be handled by fundamental prototyping processes, this method can have a positive effect on your timeframe and bottom line.

If your product is complex, rapid prototyping may eventually do more harm than good. That being said, it’s a process worth considering for your project, because rapid prototyping is becoming more affordable and available than ever before.